Antimicrobial

Stop bacterial growth on all Fastand products

Free on the whole range of Fastand products

From our research center we have created a new era in the world of surfaces for events and trade fairs. All our white products are in fact made with Antimicrobial8 to guarantee not only the quality but also the protection from bacteria of all our products.

We have introduced this new powder paint to our production cycle to increase anti-bacterial protection: from today, in fact, all of our products with a white surface are treated with Europolveri-produced Antimicrobial8.

The surface finish however remains of the highest quality and constant in Pantone Cool Gray 1C and Ral-9010 without any price increase.

Responsible and anti-bacterial.

The concern arising from the possible spread of bacterial infections and the aggressiveness and resistance shown by certain bacteria, is causing an increasingly widespread and differentiated demand for work and meeting environments equipped with safe equipment, machinery and furnishings and protected from possible bacterial proliferation .

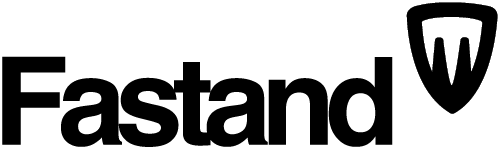

Test results

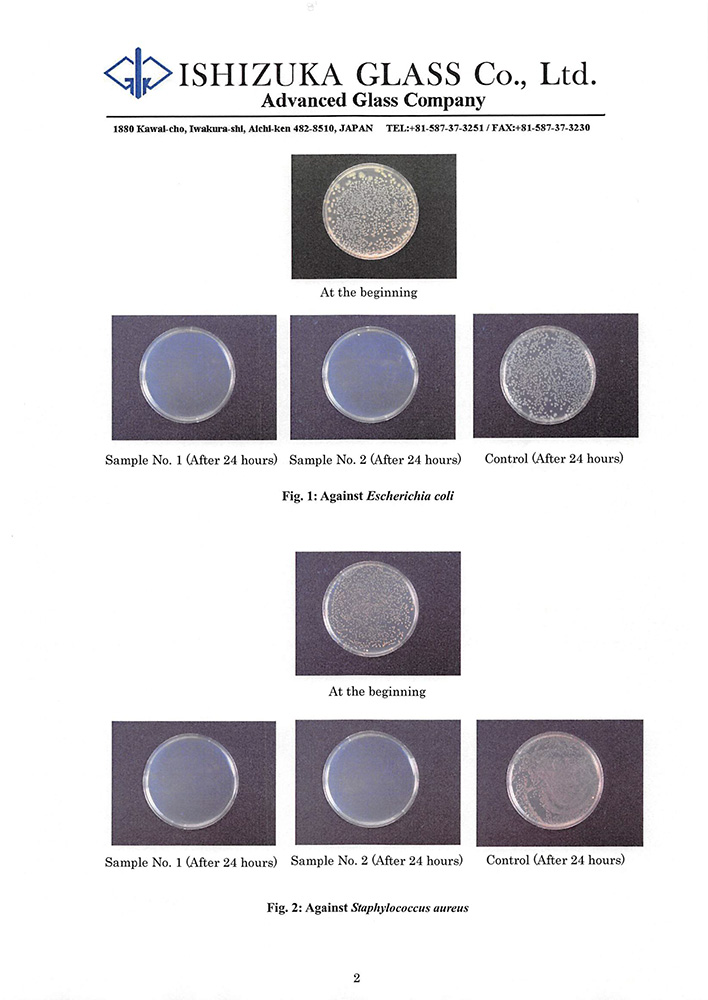

The “Antimicrobial8” treatment was subjected to antibacterial efficacy tests performed in biological laboratories according to the JIS Z 2801: 2000 standards using two of the most common bacteria:

NBRC 3972 ESCHERICHIA COLI – NBRC 12372 STAPHYLOCOCCUS AUREUS

In order to give greater value to the test, the surfaces subject to the tests were previously subjected to a heat treatment aimed at simulating an aging of ten years of use of the product indoors.

By placing a colony with a known content of bacteria on the surfaces of the coatings under examination, the count of the still active bacteria is performed after 24 hours.

The different proliferation between the product treated with a normal powder paint and “Antimicrobial8” actually establishes the antibacterial efficacy of the product.

International certificates

The presence of the antibacterial agent in the “Antimicrobial8” formulation causes a slow and constant release of silver ions over time.

This gives the treated articles marked antimicrobial characteristics which effectively prevent bacterial proliferation.

It should be noted that the inhibitory characteristics of the bacterial proliferation of “Antimicrobial8” and the guarantee of duration of efficacy do not eliminate

the need for constant and scrupulous cleaning treatments of the products.

Data sheet

PURAL PES 5L1191103T0A0 WHITE L L TS AM8 9010CA – QUALICOAT P-0476

Composition

Powder based on saturated carboxylated saturated polyester resins and hardeners alternative to TGIC selected for their external resistance characteristics.

Formulated with pigments and additives specifically chosen for their high resistance to UV rays and atmospheric agents. The specific feature of the series

ANTIMICROBIAL 8 is the presence in formulation of an inorganic antibacterial agent that gives the product marked characteristics

antimicrobial.

Properties and uses

Powder suitable for painting products in which the elimination and control of bacterial proliferation are of fundamental importance. To

example: machinery and equipment for the pharmaceutical or food industry, controlled contamination environments, sanitary equipment and furnishings and

hospital, equipment and products for the community, etc. In order to ensure good protection it is necessary to apply the powder at an average thickness of

70-80 microns.

Preparation of the support

The products adhere to all metal substrates as long as they are dry, clean and degreased. To prolong the resistance to corrosion it is advisable to carry out a

suitable chemical pretreatment of the surface according to the nature of the metal support.

Application

Product applicable by electrostatic generator guns with voltages between 40-90 kV. Where present in the description the abbreviation “TS” the products are

can also be used with the use of triboelectric guns.

Differences in thickness of the applied paint can lead to variations in the surface appearance of the hardened paint. In the case of effect products

special the use of recovery is not recommended except for bonded products (BOND).

Polymerization conditions

180 ° C x 20 ‘, 190 ° C x 15’, 200 ° C x 10 ‘(object temperature)

Characteristics of the hardened film (applications on steel sheet)

Erichsen drawing: & gt; = 5 mm ISO 1520

Cylindrical mandrel: & gt; = 4 mm ISO 1519

Impact test: & gt; = 2,5 Nm ASTM D2794

Buchholz hardness tester: & gt; = 80 ISO 2815

Adhesion test: Gt0 ISO 2409

Gardner 60 ° brilliance: 80-100 gloss ISO 2813

Chemical resistance

It has good resistance to most acids and bases at 10% and ethyl alcohol at room temperature of (25 ° C).

For specific requests it is necessary to contact our Customer Service.

Corrosion resistance (applications on Fe-phosphate bonder sheets)

Humidistat exposure: No alteration after 500 hours. ISO 6270

Accelerated corrosion Kesternich: No loss of adhesion after 10 cycles. ISO 3231

Salt Mist: After 1000 hours penetration & lt; 1 mm. ISO 9227

Accelerated aging QUV-B (313 nm) with QUV / SE cycle 4 h condenses at 40 ° C / 4 h irradiation 50 ° C (0.75 W / m² / nm. Application on Al sheet metal).

Test: Loss of gloss & lt; = 50% after 300 h. ISO 16474: 3

Storage

The product is guaranteed for 24 months from the production date if stored at a temperature not exceeding 30 ° C and in the original packaging.

Note:

Revision 3 / May. 2020

EUROPOLVERI S.p.A.

The above information is the result of careful research and our many years of experience, however taking into account the large number of

factors that contribute to the achievement of the values we describe, the user will take care of producing the optimal conditions necessary for the

achievement of the best result.

This product is intended for use in industrial plants only. The handling of the product by the user must

be carried out in accordance with the provisions for the use of powder paints and with what is reported in the safety data sheet sent together with the

product and to which you are referred.